My experience at VFSTR exploring the spinning yarn process has been transformative, blending theory with practice. Engaging in research on viscose cotton blends and simplex modifications enhanced my technical skills. As Vice President at a spinning mill, I apply this knowledge to drive innovation in yarn production, ensuring quality and sustainability. This journey has deepened my appreciation for textile engineering and the craft behind spinning.

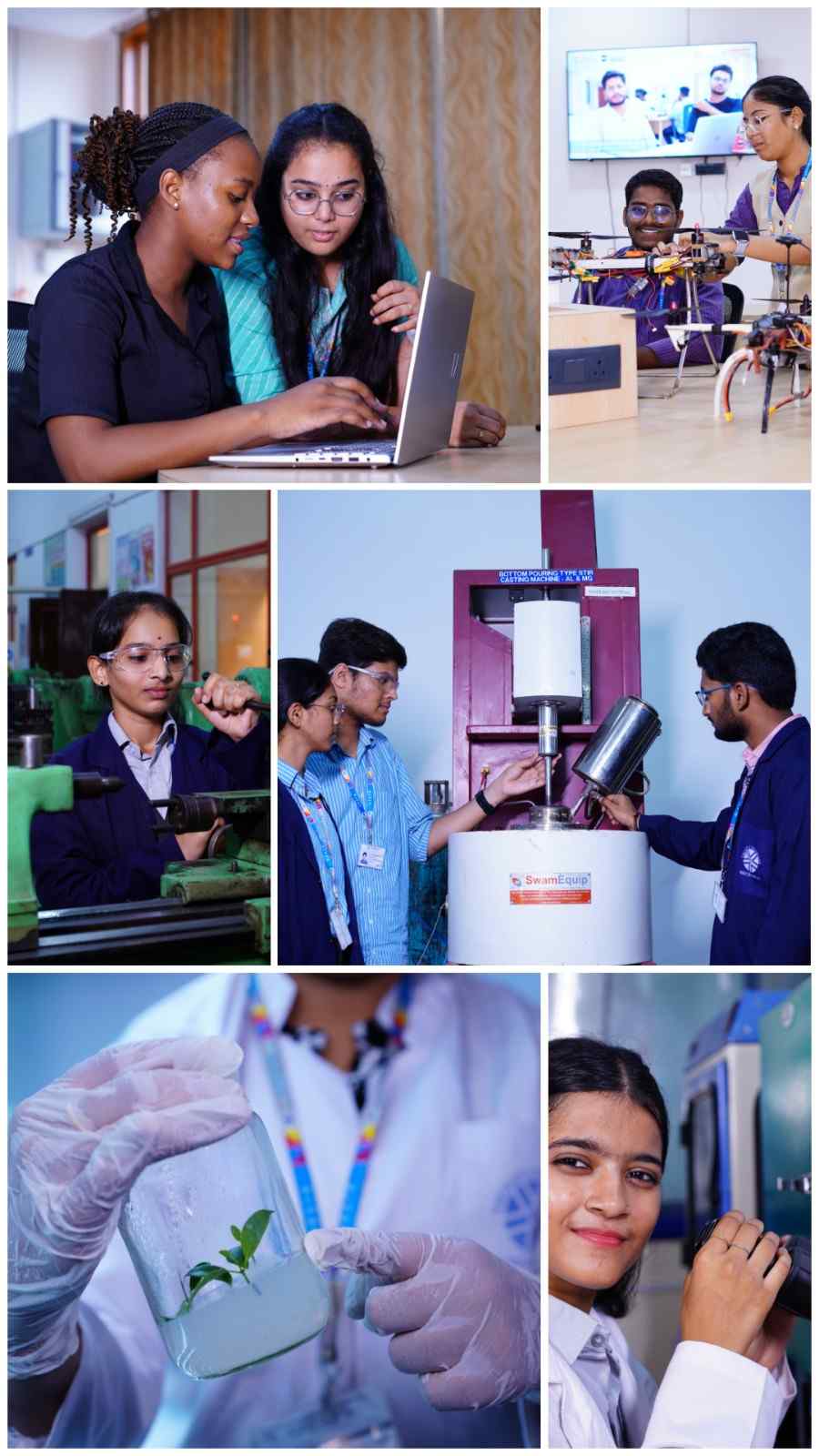

The methodology designed to calculate ARIIA metrics considers all major parameters/ indicators used globally to rank education institutions for innovation output. Additionally, ARIIA also measures some parameters which are India specific considering the current scenario and status of higher education in India.

Vignan Institute’s departments like Bio-tech, Food, Agricultural and Engineering Technologies s are part of innovation and startup ecosystem of the institute.