The Department of Mechanical Engineering at VFSTR has state-of-the art Laboratory facilities that are located mostly at Aryabhatta Block (U-Block). A total of 14 Laboratories, 4 research centers and one Center of Excellence in Composite materials, cater to the needs of academic and research requirements not only in the department but serves other departments as well.

List of Laboratories| S. No | Name of the Laboratory | Room No. | Area (Sq.mts) |

|---|---|---|---|

|

1 |

IC Engines Laboratory |

AGF-01 |

195 |

|

2 |

Mechanics of Solids Laboratory |

AGF-02 |

195 |

|

3 |

Fluid Mechanics Laboratory |

AGF-02 |

195 |

|

4 |

Hydraulic MachinesLaboratory |

AGF-02 |

195 |

|

5 |

Machine Tools Laboratory |

AGF 10 |

194 |

|

6 |

Metrology Laboratory |

AGF 10 |

194 |

|

7 |

Manufacturing Technology Laboratory |

AGF 11 |

140 |

|

8 |

Machine Dynamics Laboratory |

AFF-03 |

130 |

|

9 |

Instrumentation Laboratory |

AFF-11 |

75 |

|

10 |

Metallurgy Laboratory |

AFF-11 |

75 |

Other Laboratories

| S. No | Name of the Laboratory | Room No. | Area (Sq.mts) |

|---|---|---|---|

|

11 |

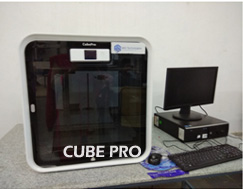

3D Printing Laboratory |

AGF-05 |

116 |

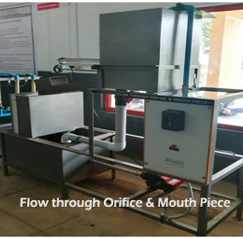

FLUID MECHANICS & HYDRAULIC MACHINARY LABORATORY

Fluid mechanics and hydraulic lab provides basic idea about fundamental of fluid mechanics with a hand on experience on principles like venturimeter, Bernoulli's etc it also deals with experiments on friction factor, power production machinery like turbines, pumps. The well-equipped lab has been providing sound knowledge to the students of mechanical, mechatronics, automobile, civil and chemical engineering departments

| Sno | Name of Equipment |

|---|---|

| 1 | Venturimeter and Orifice meter |

| 2 | Pipe Friction apparatus (Major Losses) |

| 3 | Flow through Orifice and Mouth Piece |

| 4 | Bernoulli's Apparatus |

| 5 | Loss of head due to sudden expansion contraction and Elbow (Minor Losses) |

| 6 | Flow through Notches |

| 7 | Multistage Centrifugal Pump |

| 8 | Reciprocating Pump |

| 9 | Impact of Jet on Vanes |

| 10 | Pelton Turbine |

| 11 | Francis Turbine |

| 12 | Kaplan Turbine |

Instrumentation Laboratory

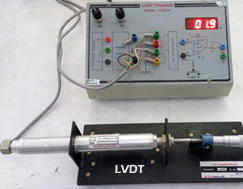

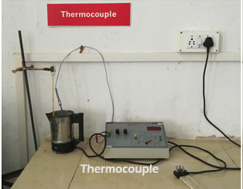

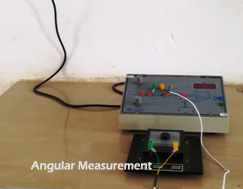

About Lab: Instrumentation is the heart of performance assurance for the modern industry. The present technologies are mainly operated by various electronic devices. In electronic devices transducer is the key element, which converts any form of signal to electrical signals. This lab gives the awareness to the student, of various transducers. The calibration of various transducers and instruments performances are studied and also analyzed the static and dynamic characteristics of the various instruments. In this lab LVDT, Thermocouple, RTD, Photo and Magnetic Speed Pickup and Angular Measurement transducers are available for practice. Equipments worth Rs. 92,523/- are available with the Lab.

| Sno | Name of Equipment |

|---|---|

| 1 | Capacitive Module for Angular Measurement |

| 2 | Linear Variable Differential Transducer (LVDT) |

| 3 | Photo Electric and Magnetic speed Pickup |

| 4 | Resistance Temperature Detector (RTD) |

| 5 | Strain Gauge |

| 6 | Thermocouple |

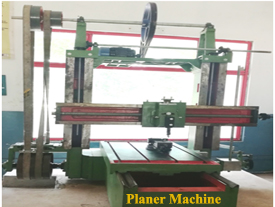

Machine Tools Laboratory

Machine tools laboratory is one of the prime laboratory in the School of Mechanical Engineering. Conventional center lathe to Capstan lathe machines are available in this laboratory. Various machining operations on lathe named as step , taper turning, facing, drilling, boring and thread cutting are carried. Shaping of flat surfaces , grinding of flat surfaces are performed using shaper and grinding machines. Gear cutting and indexing operations are performed using milling machine. Internal slots and keyways are obtained using slotting machine. Radial drilling machine is available to drill holes in the components. Equipment worth Rs. 12,19,820/- available with the Lab.

| Sno | Name of Equipment |

|---|---|

| 1 | Lathe Machine (Panther Modle) |

| 2 | Lathe Machine (Namrata Student 2 nos) |

| 3 | Lathe Machine (PL-4 Type 6 nos.) |

| 4 | Capston Lathe |

| 5 | Milling Machine |

| 6 | Slotting Machine |

| 7 | Radial Drilling Machine |

| 8 | Surface Grinding Machine |

| 9 | Shaper |

| 10 | Bench Grinder |

| 11 | Planer |

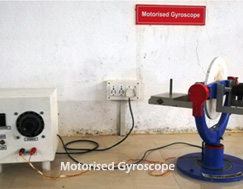

Machine Dynamics Laboratory

The Machines and Mechanisms Laboratory has a range of equipment, designed to meet the needs of students who are required to understand the basic principles of machines. The Lab includes a whirling of shafts apparatus, Universal governor apparatus, a balancing of reciprocating masses apparatus, a static and dynamic balancing apparatus, in addition to a vibration apparatus, where experiments can be performed on pendulums, springs and rotors, covering free and forced vibration, damping, and torsional oscillations.

| Sno | Name of Equipment |

|---|---|

| 1 | Static and Dynamic Balancing |

| 2 | Balancing of reciprocating masses |

| 3 | Motorized gyroscope - verification of laws |

| 4 | Whirling of shaft |

| 5 | Forced & Free Vibration - Universal Vibration apparatus |

| 6 | Governor Apparatus; Porter, Proell & Hartnell Determination of sensitivity, effort |

| 7 | Four Bar Mechanism |

| 8 | Kinematics of Gear Models |

| 9 | Kinematics of Gear Trains |

| 10 | Motor driven Four bar mechanism and Slider crank mechanism |

| 11 | Cam analyzer |

Metallurgy Laboratory

| Metallography is the science dealing with the identification of the constitution and structure of metals and alloys by use of low magnification, optical microscopes. Our Metallurgy lab includes all of the equipment necessary for the preparation of samples prior to analysis by microscopes. Cold and hot mounting options are available for small to medium sized samples. Our lab contains several grinding and polishing wheels to bring a metal cross section to a mirror finish. We will chemically etch the sample to characterize the strain structure. |  |

| Sno | Name of Equipment |

|---|---|

| 1 | Double Disc Polishing Machine |

| 2 | Jomney End Quench apparatus |

| 3 | Metallography Linisher - belt grinder |

| 4 | Muffle Furnace |

| 5 | Specimen Cutter |

| 6 | Specimen Mounting Press |

| 7 | Trinocular Metallurgical Microscope with image analysis software |

| 8 | Powder compaction die |

| 9 | Manual hydraulic press |

Metrology Laboratory

Dimensions play a vital role in the manufacturing of a component. A product quality is assured on the basis of mechanical properties as well as its accurate dimensions. This is possible by the precise measuring instruments. Various measuring tools are used in industry to obtain the dimensional accuracy of a component. In this laboratory students will obtain the knowledge of usage of various measuring instruments with hands on experience. Ring, Plug and bore gauges are used in mass production to improve the quality assurance with less effort and time. Angular measurements are made with bevel protractor and sine bar. Screw and gear features are measured with floating carriage micrometer and gear tooth calipers. Toolmakers microscope and profile projector are used to obtain precise measurements of irregular surfaces too. All these techniques will be learned in this laboratory Total cost: 4,90,844

| Sno | Name of Equipment |

|---|---|

| 1 | Verinier Calipers |

| 2 | Internal Micrometer |

| 3 | Micrometer |

| 4 | Bore gauge |

| 5 | Bevel Protractor |

| 6 | Sine Bar |

| 7 | Slip Gauges |

| 8 | Gear Tooth Vernier |

| 9 | Talysurf |

| 10 | Dial gauge (3 No.s) Dial Stand |

| 11 | Profile Projector |

| 12 | Tool Makers Microscope |

| 13 | Lathe Tool Dynamometer |

| 14 | Drill Tool Dynamometer |

| 15 | Floating Carriage Micrometer |

| 16 | Vernier height gauge |

| 17 | Surface Plate |

| 18 | Angle Plate |

| 19 | Ring & Phig Gauges |

| 20 | Venire Calipers (3 Nos.) |

| 21 | Outside Micrometer 0-25mm (2 Nos.) |

| 22 | Outside Micrometer 25 - 50mm size (2 nos.) |

| 23 | Inside Micrometer |

| 24 | Gear tooth caliper |

| 25 | Bevel Protractor |

| 26 | Sign bar |

| 27 | Three wire set micrometer holder |

| 28 | Slip Gages |

| 29 | Bore Gage |

| 30 | Screw thread micrometer |

| 31 | Vernier caliper (Digital Type) |

Mechanics of Solids Laboratory

The objective of Strength of Material lab is to demonstrate the basic principles in the area of strength and mechanics of materials to the undergraduate students through a series of experiments. Students will be conducting experiments using UTM to calculate the tensile strength of steel samples and experiments to measure hardness of non-heat treated and heat treated steels by using Rockwell, Brinels hardness testing equipments. Students will also test steel samples in single shear, double shear and impact loading followed by experiments on torsion testing machine to calculate torsional strength. The laboratory also demonstrates the important concepts from Strength of Materials theory course.

| Sno | Name of Equipment |

|---|---|

| 1 | Universal Testing Machine |

| 2 | Torsion Testing Machine |

| 3 | Impact Testing Machine |

| 4 | Vicker's Hardness Testing Machine |

| 5 | Rock Well Hardness / Brinnel Hardness Testing Machine |

| 6 | Spring Testing Machine |

| 7 | Load Vs Deflection study on cantilever beam |

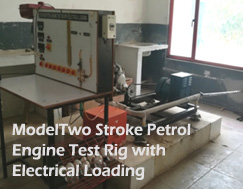

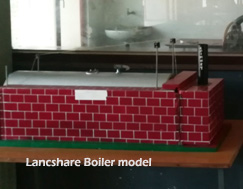

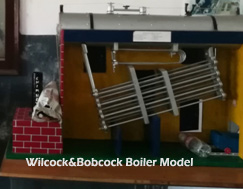

IC Engines Laboratory

| Sno | Name of Equipment |

|---|---|

| 1 | 2 - Stroke Petrol Engine Test Rig |

| 2 | Wilcox & Bobcock Boiler model |

| 3 | Lancashire Boiler model |

| 4 | Cut - section of a 2 - Stroke Diesel Engine (2nos.) |

| 5 | Cut - section of a 2 - Stroke Petrol Engine (2nos.) |

| 6 | Cut - section of a 4 - Stroke Petrol Engine |

| 7 | Computerized Variable Compression Ratio Test Rig |

| 8 | Re-circulating type Air Conditioning test rig |

| 9 | Cut - section of a 2 - Stroke Diesel Engine |

| 10 | 4-stroke High speed, Single cylinder, Vertical Diesel Engine |

| 11 | 2-Stage Reciprocating Air compressor |

3D PRINTING LABORATORY

| Sno | Name of Equipment |

|---|---|

| 1 | CUBE PRO |

| 2 | CUBE DUO |

| 3 | CUBE TRIO |

| 4 | Scanner Second Generation - Manual |

| 5 | Elite object scanner - Automatic |