- Research

- CoE

- Research Centers

- Research Fellows

Department of Mechanical Engineering consists of a strong team in Research and Development.The thrust areas of research are fludized bed combustion, bio mass and solar energy utilization, composite materials, Nanocomposites and hybrid composites. Faculty of this school are actively involved in research publications in the various reputed journals and conferences

| Name of the teacher provided with seed money | Title of the Seed Project |

|---|---|

|

Dr. L. RatnaRaju |

3-D printed Muscle sensored prosthetic arm |

|

Dr.K.Balamurugan |

Fabrication, characterization and machining of aluminium composite with 63% of SiC |

|

Dr.K.Balamurugan |

Fabrication and property evaluation of metal, polymer, ceramic particles as reinforcement in PLA based composite filament for fused deposition modelling technology |

|

Dr M.Ram Krishna |

Vignan's Rotating Emblem |

|

Dr. D. Satyanarayana |

Measurement & Analysis of wire vibration in wire electric discharge machining |

|

Dr. K. V. Rao |

Modeling and Optimization of weld geometry using Artificial Intelligence and HTLBO |

|

Dr. L. S. Raju,Mr. T.N.B. Prakash |

Multi-objective optimization of Friction Stir Weldments of AA2014-T651 by TLBO |

|

Dr.G. Suresh |

An experimental study to maximize performance of micro milling for Ti-6Al-4V |

|

Dr.D. Vinay Kumar, |

Design and Fabrication of Compact Heat Exchanger for Multiple Purpose Usage |

|

Mr. T. Ch. Anil Kumar, |

Development of Analytical Approach for Generating Balanced Gaits of a Biped Robot on Stairs and Sloping Surfaces |

|

Ms. Y. Jyothi, Mr. B. J.M. Rao& |

Reliability and maintainability analysis of complex repairable system: a case study of railways |

|

Mr.M.Ravi Kumar |

Design and Development of Coconut Tree Climbing Robot |

Fellowships

| Name of the Teacher awarded National/ International Fellowship / Financial support | Name of the Award / Fellowship |

|---|---|

|

Mr. P. Manoj Kumar |

Research Assistance Fellowship |

|

Mr. Manoj Kumar |

Research Assistance Fellowship |

|

Mr. Tulluri C Anil Kumar |

Quality Improvement Programme |

|

Mr. K. Pradeep Chand |

Quality Improvement Programme |

|

Mr. E. Govinda Rajulu |

Quality Improvement Programme |

|

Mr. Vidyadhar Karlapalem |

Research Assistance Fellowship |

|

Mr.M. Vinod Babu |

Research Assistance Fellowship |

|

Mr. P. Madhukar |

Research Assistance Fellowship |

|

Dr. D. Vinay Kumar |

Post Doctoral Fellowship |

Extramural funding - Non Government organizations

| Year | No.of Projects | Amount (INR in Lakhs) |

|---|---|---|

|

2019-20 |

12 |

4.44 |

|

2018-19 |

31 |

6.47 |

|

2017-18 |

8 |

5.41 |

|

2016-17 |

8 |

3.1 |

Govt. funded Research Projects

Faculty of this school are actively involved in the research projects. DST and SERB government projects were carried out in the field of Advanced Manufacturing, Bio-Fuels and Socio-Centric and solar energy fields.

List of Projects (Ongoing/PCR Submitted)| S.No | Title of the project | Funding agency | Principal Investigator | Status | Amount sanctioned (Rs./-) |

|---|---|---|---|---|---|

| 1 | Cost Effective Automated Additive Manufacturing Hub for Sustainability of MSMEs (under AMT category) | DST | Mr. T. Ch. Anil Kumar, Mr. N. Bhanu Prakash T. | 2022-2025 (On going) | 98,03,412 |

| 2 | VFSTR –NIDHI Inclusive TBI (i-TBI)(Under Innovation & Entrepreneurship Theme) | DST | Dr. Vijaya Ramu D (Bio-Tech),Dr. B. Nageswara Rao (Mech) | 2022-2025 (On going) | 4,49,50,000 |

| 3 | STI HUB for income generation and livelihood improvement of schedule caste community of Guntur District, AP. | SEED-DST | Dr. K.V. Krishna Kishore (CSE)Dr. D. Vinay Kumar (MECH) | 2021-24(On going) | 169 lakhs |

| 4 | Solar Based Technologies for clean water and sewage treatment in Veldurthi Village, Guntur district, AP. | TMD-DST | Dr. Vinay Kumar | 2021-24(On going) | 2,55,00,000 |

| 5 | Experimental Investigation of influence of Ultrasonic vibration on Micro structure and Mechanical Properties of FSPED Aluminium alloy | DST-EMEQ | Dr. Lam Suvarna Raju | 2019-22(PCR Submitted) | 3205000 |

| 6 | Formulation and optimization of Iso-stoichiometric Ternary Gasoline-Alcohol Blends and Investigation of their Influence on a Spark Ignition Engine | SERB, DST | Dr. D Vinay Kumar | 2017-2020 (PCR Submitted) | 21,62,000 |

| S.No | Title of the project | Funding agency | Principal Investigator | Status | Amount sanctioned (Rs./-) |

|---|---|---|---|---|---|

| 1 | Vibration Measurement and Analysis | DST,-FIST/ New Delhi | Head of the Department | Completed | 47,00,000 |

| 2 | Performance and Emission Studies of Algae Biodiesel in a CI Engine Equipped with Diesel Particulate Filter. | DST, New Delhi | Dr. D. Jagadish | Completed | 24,81,000 |

| 3 | Modernization of Computer Aided Design / Computer Aided Manufacturing Laboratory | MODROBS, AICTE, New Delhi | Dr. K. Phaneendra Kumar | Completed | 7,00,000 |

| 4 | Development of New Hybrid Composite Material and its characterization | APCOST Hyderabad | Dr. K. Phaneendra Kumar, Mr. P.B.G.S.N. Murthy | Completed | 7,500 |

| 5 | Augmentation of Thermal Conductivity of Nanofluids | AICTE, New Delhi | Dr. K. Phaneendra Kumar | Completed | 6,90,000 |

| 6 | Bi-Liquid Solar Cooker | APCOST Hyderabad | Mr. B.J.M. Rao | Completed | 7,500 |

| 7 | Fabrication of Bio - degradable Composites | APCOST Hyderabad | Dr. K. Phaneendra Kumar | Completed | 7,500 |

| 8 | Hydrodynamics of Municipal Solid waste pellets | APCOST Hyderabad | Dr. K.V.N. SrinivasaRao | Completed | 7,500 |

| 9 | Design and Fabrication of Solar Pressure Cooker | APCOST Hyderabad | Dr. K.V.N. SrinivasaRao | Completed | 7,500 |

| 10 | Low Cost Water Cooling System | APCOST Hyderabad | Dr. K.V.N. SrinivasaRao | Completed | 3,375 |

| 11 | Hydrodynamics of Rice Husk in Fluidized Bed | APCOST Hyderabad | Dr. K.V.N. SrinivasaRao | Completed | 5,000 |

| 12 | Combustion of Agro Waste with Fluidized Bed Technique | DST, New Delhi | Dr. K.V.N. SrinivasaRao | Completed | 3,60,000 |

| Year | No. of Publications |

|---|---|

|

2019-20 |

49 |

|

2018-19 |

38 |

|

2017-18 |

6 |

|

2016-17 |

0 |

|

2015-16 |

0 |

|

Total |

93 |

| Year | No. of Publications |

|---|---|

|

2020 |

32 |

|

2019 |

55 |

|

2018 |

44 |

|

2017 |

32 |

|

2016 |

21 |

|

2015 |

3 |

|

Total |

187 |

| Year | No. of Projects | Amount (INR) |

|---|---|---|

|

2019-20 |

3 |

710000 |

|

2018-19 |

3 |

400000 |

|

2017-18 |

5 |

935000 |

|

2016-17 |

5 |

810000 |

|

2015-16 |

1 |

80000 |

The Institution aims to make experts in the areas of composites and play a role in transforming solutions to the existing problems of manufacturing.

- Development of High performance rigid composites made from glass, graphite, kevlar, boron or silicon carbide fibers in polymeric matrices in aerospace and space vehicle technology applications.

- Development of Secondary fiber (from waste virgin products like Flexes, bottles, disposable glasses etc.) reinforced polymeric composites for low costapplications.

- Facilitates UG, PG students and Ph.D. Scholars to understand the theory and application of composites across multiple technological disciplines.

- Impart practical exposure on the various methods and practices of composites technology.

- To provide the experience and expertise for participating in major research programs.

- Provide a career-path to the Faculty in the emerging area of composites.

| S. No. | Year of Purchase | EQUIPMENTS | COST |

|---|---|---|---|

|

1 |

2014 |

Digital Vickers Micro Hardness Tester |

665000 |

|

2 |

2015 |

Drum Winding machine |

360000 |

|

3 |

2015 |

Hydraulic Press |

571672 |

|

4 |

2016 |

Universal Testing Machine |

1112119 |

|

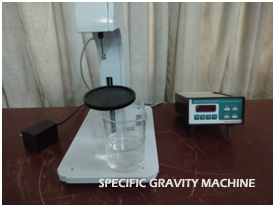

5 |

2017 |

Electronic specific gravity balance |

92,580 |

|

6 |

2017 |

Melt flow Index tester |

200895 |

|

7 |

2017 |

Impact test machine, Izod type |

45,000 |

|

8 |

2017 |

Computerized electronic Tensile Testing Machine |

598320 |

|

9 |

2017 |

Circulating oil bath with cooling unit |

82,425 |

|

10 |

2017 |

Components of oil bath |

60,220 |

|

11 |

2018 |

Pin on Disc Tribometer |

420000 |

|

12 |

2018 |

FLIR Thermal image camera |

661095 |

|

13 |

2018 |

Fatigue Testing machine |

114030 |

|

14 |

2019 |

Stir casting Machine |

1356201 |

|

15 |

2019 |

Stereo zoom microscope |

210000 |

|

|

65,49,557 | ||

| S.No | Name | Regd.No | Enrolment Date | Title | Guide |

|---|---|---|---|---|---|

|

1 |

G.SRIKAR |

101PG08002 |

02-09-2010 |

Effect of De-lamination on the mechanical properties and GFRP Composites |

DR. K. PHANEENDRA KUMAR |

|

2 |

K VENGAL RAO |

121PG08202 |

01-04-2013 |

Critical Analysis of resin flow charactriristic in a controlled volume mould cavity for improving the FRP composites with RJM Process |

DR. K. PHANEENDRA KUMAR |

|

3 |

S DEVARAJ |

141PG08004 |

22-09-2014 |

Studies on Nano Filler Reinforced Epoxy based Hybrid composites. |

DR. M. RAMA KRISHNA |

|

4 |

SURESHKUMAR B |

141PG08006 |

20-09-2014 |

Characterization of Nano-Composite Materials Subjected to flexural fatigue Analysis |

DR. K. PHANEENDRA KUMAR |

|

5 |

A KIRAN KUMAR YADAV |

141PG08201 |

23-04-2015 |

An investigation of hygro-thermal influence on GFRP composites. |

DR. K. PHANEENDRA KUMAR |

|

6 |

VOTARIKARI RAJESH |

141PG08204 |

23-04-2015 |

Investigation of Carbon composites subjected to different environmental conditions. |

DR. P M V RAO |

|

7 |

PAVANI KUMARI N |

151PG08003 |

17-10-2015 |

study on carbon fiber reinforced polyproylene hybrid composite |

DR. M. RAMA KRISHNA |

|

8 |

GARIGIPATI R K SWAMI |

161FG08003 |

12-09-2016 |

Studies on polybenzoxazine hybrid composites |

DR M RAMA KRISHNA |

|

9 |

Mukku Venkataiah |

161FG08002 |

06-09-16 |

Investigation of Mechanical Properties & Machining Characteristics of Friction Stir Processed(FSP) ZE41 Mg based Alloy |

DR.K.Venkatarao |

|

10 |

YARLAGADDA JYOTHI |

161PG08004 |

14-09-2016 |

Influence of nanoparticles on the properties of glass/carbon fibre reinforced epoxy composites |

DR M.RAMAKRISHNA |

|

11 |

RAKESH TEJ KUMAR K |

161PG08201 |

23-01-2017 |

Analysis of Nano Composite Coated PV- System with Priority Energy Management System |

DR M.RAMAKRISHNA |

|

12 |

Chinna Basha |

171FG08201 |

25-01-18 |

Fabrication and Property Evaluation of Hybrid Al 7075 metal matrix composite |

Dr.K.Balamurugan |

|

13 |

M.Venkata Pavan |

171FG08203 |

10-02-18 |

Evaluation of material properties on PLA-Copper filler samples prepared by fused deposition model |

Dr.K.Balamurugan |

|

14 |

G.Pruthvi Raju |

181FG08002 |

01-08-18 |

Fabrication and Machining studies on AlSi7 and SiC Hybrid Composite |

Dr.K.Balamurugan |

|

15 |

Sneha |

181FG08203 |

02-05-19 |

Preparation and machining studies of Al/LaPo4 ceramic composite |

Dr.K.Balamurugan |

| Sno | Faculty Name | Book Title | ISBN No. | Remarks | Publisher Details |

|---|---|---|---|---|---|

| 1 | Dr. M S C Bose & Dr. K. Phaneendra Kumar | Proceedings of the National Conference - Advances in Mechanical Engineering | 978-93-82163-03-9 | Book | Paramount Publishing House |

| 2 | Mr. T Anup Kumar | Numerical simulation of natural convection in a squareenclosure with horizontal heat sources of different geometries | 978-93-82163-03-9 | Chapter in book | Paramount Publishing House |

| 3 | Mr. N. Narayan Rao | Modelling and simulation of Stewart platform | 978-93-82163-03-9 | Chapter in book | Paramount Publishing House |

| 4 | Mr. T Sunil Kumar | forced vibration analysis of a cracked composite beam | 978-93-82163-03-9 | Chapter in book | Paramount Publishing House |

| Year of Enrolment | Name of Research Fellow |

|---|---|

|

2022-23 |

Malladi Krishna Prasad |

|

2022-23 |

Sirapu Sirisha |

|

2022-23 |

D.Prathyusha |

|

2022-23 |

G Sridevi |

|

2022-23 |

M Balakrishna |

|

2022-23 |

S Bhaskar |

|

2021-22 |

K Priyanka |

|

2021-22 |

Gill Santosh Kumar |

|

2021-22 |

C Reddy Prasad |

|

2021-22 |

Me Annadiorai |

|

2021-22 |

Selvamuthukumar M |

|

2020-21 |

G Sudharshan Reddy |

|

2020-21 |

Naveen Reddy |

|

2019-20 |

V Nagasudha |

|

2019-20 |

N.M.K. Sarath Kumar |

|

2019-20 |

Anabathula Udaya Sri |

|

2019-20 |

Anabathula Udaya Sri |

|

2019-20 |

Abshalomu Yallamati |

|

2019-20 |

M K S Kumar Nagoju |

|

2019-20 |

Vasamsetty Naga Sudha |

|

2019-20 |

A Harikishan |

|

2019-20 |

Kammani Srinivasarao |

|

2019-20 |

V V Krishna Vandana |

|

2019-20 |

Pavan Chandu Boda |

|

2018-19 |

Shaik Abrar |

|

2018-19 |

Feroz Shaik |

|

2018-19 |

K Pavan Kumar Reddy |

|

2018-19 |

Gopalakrishna V |

|

2018-19 |

Ch Divya |

|

2018-19 |

Sekhar Chinthamreddy |

|

2018-19 |

Emani Siva Krishna |

|

2018-19 |

Garikapati Pruthvi Raju |

|

2018-19 |

Gundala Samhita Priyadarshini |

|

2018-19 |

P Satish Kumar |

|

2018-19 |

Srirami Reddy Kamireddy |

|

2018-19 |

Maguluri Nagarjuna |

|

2018-19 |

Shaik Subani |

|

2018-19 |

Sneha P |

|

2018-19 |

Chelamalasetti Pavan Satya Narayana |

|

2018-19 |

Kunchala Balakrishna Reddy |

|

2018-19 |

Arunkarthikeyan K |

|

2018-19 |

Juluru Pavanu Sai |

|

2017-18 |

Vayalapalli Bhogeswara Rao |

|

2017-18 |

Nandure Narayan Rao |

|

2017-18 |

Farooq Shaik |

|

2017-18 |

Deepthi T |

|

2017-18 |

Mihir Barman |

|

2017-18 |

N B Prakash Tiruveedula |

|

2017-18 |

M Chaitanya Reddy |

|

2017-18 |

I Bhavya Swathi |

|

2017-18 |

Vookoti Uma Sai Vara Prasad |

|

2017-18 |

Aspari Chinnamahammad Bhasha |

|

2017-18 |

Thotti Sreedhar |

|

2017-18 |

Munagoti Venkata Pavan |

|

2016-17 |

Kusumba Mangapathi Rao |

|

2016-17 |

Bachina Harish Babu |

|

2016-17 |

Veeranjaneyulu Itha |

|

2016-17 |

Yarlagadda Jyothi |

|

2016-17 |

N Ramakrishna |

|

2016-17 |

Borigorla Venu |

|

2016-17 |

Mukku Venkataiah |

|

2016-17 |

Garigipati R K Swami |

|

2015-16 |

D Madhava Reddy |

|

2015-16 |

Madduri Rajkumar Reddy |

|

2015-16 |

Pavani Kumari N |

|

2015-16 |

A. Thirumala Vasu |

Coordinator: Dr. K VenkataRao

Technical Staff: Mr. Ch.Puttaiah

Research Staff: Mr. V UmasaiVara Prasad, Mr. B Harish Babu

Objectives

List of Projects

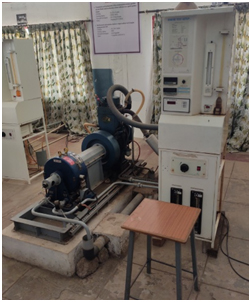

1. Vibration Measurement and Analysis; Funding: Rs. 47 lakhs (2015-2020)

Agency: FIST (DST) Principal Investigator:Dr. L Suvarna Raju (HOD)

State of art facilities

In this machine tool diagnostics lab, there are 3 tri axial accelerometer available. With these accelerometer, machine tool, cutter and tool vibrations are measured simultaneously in X, Y and Z directions in time domain. The vibration signals are processed and converted in to frequency domain with the help of the fast Fourier transformer. There is another facility of electric discharge machining machine available. Power consumption and aerosol emissions can be studied on the EDM.

| S. No. | Name of equipment | Supplier | Date of purchase | Cost Rs. |

|---|---|---|---|---|

|

1 |

Tri axial accelerometers with bnc connector ranging from 3G to higher 3No.s |

SaiViswasolutions, Vishakapatnam |

17-10-2016 |

22,23,900 |

|

2 |

16 channel multi analyser with 1/3rd octave analyser |

|||

|

3 |

FFT analyser |

|||

|

4 |

CNC flex mill |

M Tab engineers Pvt. Ltd, Chennai |

06-11-2012 |

8,39,284 |

|

5 |

CNC flex turn |

10-11-2014 |

11,24,491 |

|

|

6 |

Electrical discharge machining (EDM) machine |

Electronica India limited, Pune |

31-07-2021 |

6,82,500 |

Technical Staff : Mr. A. Jagan Mohan

Research Staff : Ms. G.S.Priyadarshini, Mr. Sk.Subani

Objectives

| Equipment | Cost(Rs.) |

|---|---|

|

Computerized Single cylinder 4 stroke SI engine |

4,60,200 |

|

Computerized Single cylinder4 strokeDieselEngin |

6,01,875 |

|

Electronic Control Unit enabled fuel injection system for petrol engine |

68,720 |

|

AVL Exhaust Gas Analyzer |

3,09,000 |

|

Netel Smoke meter |

1,05,000 |

- Computerized Single cylinder 4 stroke SI engine-4,60,200

- Computerized Single cylinder4 strokeDieselEngin-6,01,875

- Electronic Control Unit enabled fuel injection system for petrol engine-68,720

- AVL Exhaust Gas Analyzer-3,09,000

- Netel Smoke meter-1,05,000

- Supplement the engineering knowledge with the specialized experimentation and simulation skills on IC engine testing and evaluation

- Bring together the laboratory facilities, knowledge management, solutions and training, to enable the institution to quickly address real-life engineering challenges by developing the proof of concept and by experimental measurement

- Producing skilled human resources with focus on research and development by training the UG, PG and PhD scholars on alternate fuels formulation, testing and engine evaluation

- Across the university 7 projects were carried out by the B Tech students.

- 6 Ph D Scholars Have been carrying out their research work.

- Manoj Kumar E., Jagadish D., Bharath Kumar R., A note on algae as potential source for alternate fuels - Biodiesel, International Journal of PharmTech Research, 6(6), 2014, 1783-1793

- T. Sreedhar, B. Nageswararao, D. Vinaykumar, Heat transfer enhancement with different fluids in double pipe heat exchanger by ansys fluent, International Journal of Mechanical and Production Engineering Research and Development, 2019, 59-65

- D. Vinay Kumar, Farooq. Sk, Amarnatha Reddy and Vamsi Krishna (2018), Effect of velocity ratio of impinging turbulent jets on heat transfer characterstics of heat sink, International Journal of Mechanical Engineering and Technology (IJMET), 9 (8), 1093-1101

- VedullaManoj Kumar., B NageswaraRao., SkFarooq, Thermal Analysis of Rectangular and Tapered Pin fins heat sink using Icepak, International Conference on Allied Technologies in Electrical & Communication systems, 2016, 1-4

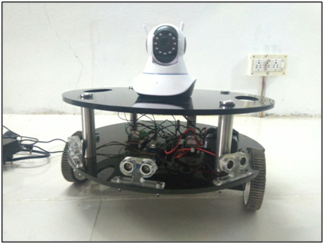

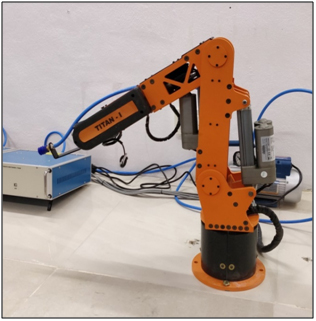

Robotics is one of the emerging fields in current global scenario. Moreover, knowledge of robotics is essential for all graduates to be successful in their upcoming career. The field of robotics is a blend of diversified areas like Mechanical, electrical, electronics and computer science. Robotics involves design, development and operation of various robots such as, mobile robots, humanoids, service robots and industrial robots. The primary objective of the "center for robotics" is to familiarize the students in various components, functionalities and their capabilities to involve for developing several types of robots which are used in the industrial and non-industrial applications. Moreover, the students should able to learn to write the programs for various path planning algorithms which are used in several applications.

IRB 1520 Welding Robot

The laboratory is utilizing for demonstration of laboratory experiments for different streams of students like 3rd year students undergoing open elective course, 4th year Mechanical and Mechatronics Engineering students undergoing Robotics course.

Moreover, we are also planning to conduct hands on experience training for students from other surrounding engineering colleges.

Right place for creative minds...

Welcome to a place with 45-year legacy of Academic Excellence. As you explore, you begin to find yourself in a well diversed and intellectually intriguing atmosphere

Copyrights © 2023 Vignan University. All rights reserved.